Machining NICER’s Patches

This video shows Richard Koenecke, an engineer at NASA’s Goddard Space Flight Center, creating the body of one of the NICER (Neutron star Interior Composition Explorer) patches.

0:00 Two blocks of aluminum sit on a counter in front of a laptop that displays the schematics for the NICER patches. 0:06 Koenecke puts one block on the bed of a saw littered with metal shavings and then trims the block. 0:23 Koenecke sands down the block’s rough edges. 0:30 Koenecke walks into another part of his workshop. 0:37 Koenecke preps the machining chamber. 0:49 Inside the chamber, the machine starts to carve out the shape of the patch. Fluid sprayed from the nozzles above the tool helps cool the metal. 0:56 Koenecke looks into the chamber. 0:59 The chamber is shown at different angles. 1:15 Koenecke walking up to the chamber window. 1:22 Inside the chamber, the patch’s shape is now visible amidst a sea of aluminum shavings. 1:25 The cutting tool refines the shape of the patch. 1:40 Koenecke looks at a computer readout for the machining chamber. 1:45 Inside the chamber, the cutting tool lowers to hollow out the patch. 1:56 Koenecke holds and turns a block of the aluminum. 2:45 Koenecke’s dog Sara guards his shop on the Eastern Shore. 2:53 Koenecke sands a block of aluminum. 3:01 He closes the doors to the machining chamber and adjusts the settings on a computer screen. 3:10 Numbers change on the chamber’s computer screen. 3:31 Koenecke holds and turns the fully machined patch body. 3:51 In slow motion, Koenecke walking through his shop. 4:25 In slow motion, Koenecke holds the patch in close-up shots.

Credit: NASA/Sophia Roberts and Scott Wiessinger

In Spring 2024, Richard Koenecke, an engineer at NASA’s Goddard Space Flight Center, created patches for NICER (Neutron star Interior Composition Explorer) in his workshop in Greensboro, Maryland. The patches are made from solid blocks of aluminum that Koenecke whittled down and hollowed out using specialized equipment.

NICER is an X-ray telescope on the International Space Station located near the starboard solar array.

In May 2023, it developed a “light leak,” where unwanted sunlight began entering the instrument. The leak is the result of damage to some of the thin thermal shields that cover the mission’s 56 X-ray concentrators, which focus X-rays onto the telescope’s detectors.

The damage allows sunlight to reach the detectors inside the telescope during the station’s daytime, saturating sensors and interfering with NICER’s X-ray measurements. The damage does not impact nighttime observations.

The NICER team developed a plan to cover the largest areas of damage using these patches, each shaped like a piece of pie, inserting them into the sunshades and locking them in place.

This slow-motion video compilation shows Richard Koenecke working on a NICER patch in his machine shop.

0:00 Pan along the main machining chamber’s computer screen. 0:03 Koenecke watches the chamber as the cutter inside begins to shape a patch from a block of aluminum. 0:18 Koenecke’s hand makes an adjustment on the chamber’s computer. 0:26 Koenecke cleans up a partially machined patch inside the chamber. 0:42 Outside of the machining chamber hangs a clipboard with a schematic of the NICER patch. 0:50 The camera’s focus gradually shifts from the outside to the inside of the chamber. 1:03 Inside the chamber, the mill begins to hollow out the patch. 1:23 Numbers fluctuate on the chamber computer. 1:33 Koenecke holds the hollowed patch. 1:54 Koenecke enters the shop.

Credit: NASA/Sophia Roberts and Scott Wiessinger

NASA Goddard engineer Richard Koenecke holds a NICER patch body in his machine shop in Greensboro, Maryland.

Credit: NASA/Sophia Roberts

Alt text: Photo of a man holding a hollow triangular silver wedge.

Descriptive text: A man in a green plaid shirt, black apron, and black baseball cap holds a shiny silver triangular wedge in front of him with one hand. The wedge is hollow. The man is centered in the frame, and behind him are blue and gray pieces of equipment.

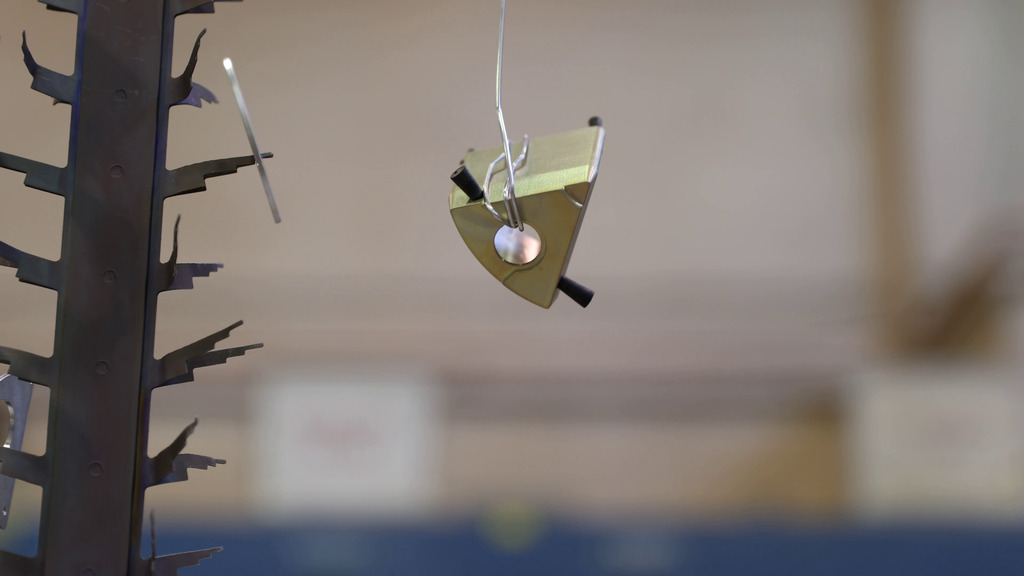

A mill in Koenecke’s machine shop hollows out a NICER patch body. A coolant fluid is sprayed onto the mill-bit to keep it from getting too hot.

Credit: NASA/Sophia Roberts

Alt text: Photo of a piece of machinery.

Descriptive text: A mill-bit whirls in this photo. It extends from the top of the frame and has several nozzle attachments that spray the mill-bit with a tannish fluid. The mill is carving out the inside of a triangular block of aluminum held in a clamp. The interior of the milling-machine chamber is littered with aluminum shavings.

Koenecke reaches into a machining chamber to remove a NICER patch that has just been carved from a block of aluminum.

Credit: NASA/Sophia Roberts

Alt text: Photo of a man with his hand extended into a machine chamber.

Descriptive text: A man in a green plaid shirt, black apron, and black baseball cap reaches with one arm into a machining chamber. The chamber has a sliding door with windows and the walls lean inward toward a mill that’s been retracted to the ceiling. The mill is a motorized spindle surrounded by several orange coolant nozzles pointed at the bit. It’s next to a set of nested black cylinders holding additional tools. On the base of the chamber is a clamp holding a triangular wedge of aluminum. The wedge is surrounded by metal shavings.

The body of a NICER patch rests amid a sea of aluminum shavings after a mill carved it from a block of aluminum.

Credit: NASA/Scott Wiessinger

Alt text: Photo of a metal wedge in a pile of metal shavings.

Descriptive text: This vertical photo centers a triangular wedge of shiny aluminum. It’s surrounded by gray metal shavings, some of which cling to its edges. Several screws extend from the edge of the platform the wedge rests on. The background shows a tan metal wall.

Credits

Please give credit for this item to:

NASA's Goddard Space Flight Center. However, individual items should be credited as indicated above.

-

Videographers

- Sophia Roberts (Advocates in Manpower Management, Inc.)

- Scott Wiessinger (KBR Wyle Services, LLC)

-

Science writer

- Jeanette Kazmierczak (University of Maryland College Park)

-

Technical support

- Aaron E. Lepsch (ADNET Systems, Inc.)

Release date

This page was originally published on Tuesday, July 30, 2024.

This page was last updated on Friday, June 28, 2024 at 2:03 PM EDT.